Contact Us

PVDF Aluminum Honeycomb Panel

- Product Type: PVDF coating honeycomb panel

- Place of origin: Foshan city, China

- Model No:

- Price Terms: FOB/CIF

- Payment Terms: TT/LC

- Package: Plywood case

- Minimum Order: 1 piece

- Delivery Time: 14days

- Brand Name:

- Inquire Online

Products Information

Product Description

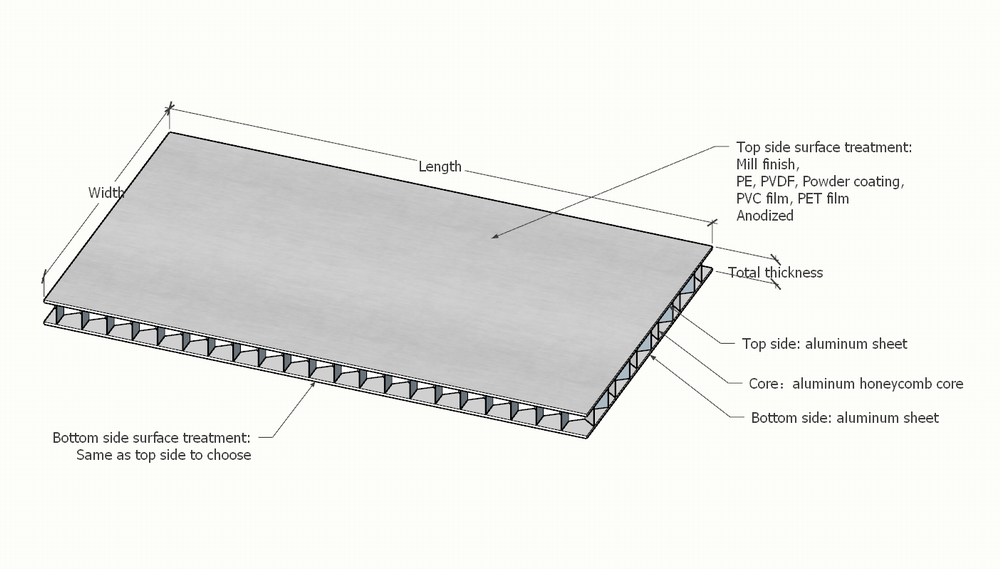

Aluminum honeycomb panel is a sandwich structure composite material developed on the basis of aerospace technology. It is made of an frontr and bottom two-layer strength aluminum alloy plate and an intermediate aluminum honeycomb core bonded by high temperature and high pressure composite process. Its unique honeycomb core structure gives it the characteristics of light weight, high strength and high stiffness, which is the ideal material for construction, transportation, decoration and other fields.

Material composition panel/bottom plate: 3003H24, 5052AH14 and other high-strength aluminum alloy plate, thickness 0.4-3.0mm, the surface can be fluorocarbon spraying, heat transfer, drawing, oxidation and other treatment, to meet the diversified decorative needs. Honeycomb core: Hexagonal aluminum foil honeycomb core (side length 5-12mm, aluminum foil thickness 0.04-0.06mm), through the honeycomb porous structure to disperse stress, improve the overall stability. Adhesive: two-component polymer epoxy adhesive or aviation grade film to ensure the bonding strength and durability of the composite layer.

Product Parameters

|

Place of Origin |

China |

|

Brand Name |

EIGHTBOND |

|

Product Name |

Aluminum Honeycomb Panel of Building Construction Materials |

|

Material |

Aluminum honeycomb+Aluminum sheet |

|

Surface treatment |

PE, PVDF, POWDER coated, PP,PET,PVC Film coated (customizable) |

|

Aluminum Foil Thickness |

Customizable (0.035mm-0.08mm) |

|

Aluminum Honeycomb Core Density |

common 4*4mm,5*5mm,6*6mm, other could be choosed |

|

Size |

Within 1200mm*2400mm,other size customized |

|

Thickness |

4mm-200mm |

Advantages:

• Lightweight yet strong • High stiffness and stability

• Excellent fire resistance

• Sound and thermal insulation

• Corrosion resistance

• Easy installation and maintenance

• Eco-friendly and recyclable

• Versatile design options

Application:

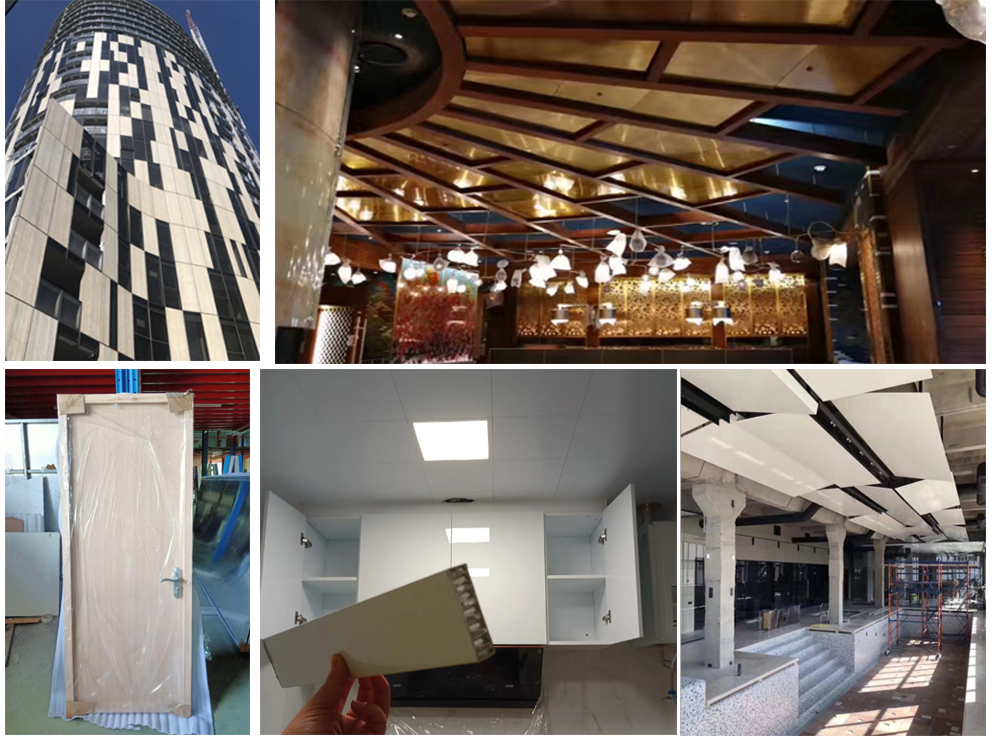

• Architectural cladding and facades

• Interior wall and ceiling panels

• Flooring and raised floors

• Partitions and dividers

• Furniture components

• Marine and aviation interiors

• Cleanrooms and laboratories

• Exhibition and display stands

| Thickness | Unit | 6 mm | 10 mm | 15 mm | 20 mm | 25 mm | |||

| Cover sheet thickness, front | [mm] | 1.0 | |||||||

| Cover sheet thickness, rear | [mm] | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |||

| Weight | [kg/m²] | 4.7 | 5.0 | 6.7 | 7.0 | 7.3 | |||

| Technical properties | |||||||||

| Section modulus | W | [cm³/m] | 2.6 | 4.6 | 14 | 19 | 24 | ||

| Rigidity | E@J | [kNcm²/m] | 7.100 | 21.900 | 75.500 | 138.900 | 221.600 | ||

| Alloy / Temper of Aluminium Layers | Peraluman alloy (AIMg), H42 acc. EN 573-3 | ||||||||

| Modulus of Elasticity | E | [N/mm²] | 70.000 | ||||||

| Tensile Strength of Aluminium | R m | [N/mm²] |

|

||||||

| 0.2 % Proof Stress | R p0,2 | [N/mm²] |

|

||||||

| Elongation | A 50 | [%] |

|

||||||

| Linear Thermal Expansion | α | 2.4 mm/m at 100ºC temperature difference | |||||||

| Core | |||||||||

| Aluminium foils from AIMn alloys (EN AW-3003) Bare comprehensive strength | [N/mm²] | > 2.5 | |||||||

| Weight | [kg/m³] | > 50 | |||||||

| Surface | |||||||||

| Lacquering |

Coil Coating Fluorocarbon based (e.g. PVDF) |

||||||||

| Gloss (initial value) | [%] | 25-40 | |||||||

| Pencil Hardness | HB-F | ||||||||

| Acoustical Properties | |||||||||

| Sound Absorption Factor | α s | 0.05 | |||||||

| Airborne sound insulation index (acc. to ISO 717-1, ISO 140-3) | R w | [dB] | 21 | 21 | 22 | 23 | 25 | ||

| Thermal Properties | |||||||||

| Termal conductivity (regarding total thickness, incl. cover sheets) | λ | [W/mK] | 0.95 | 1.35 | 1.78 | 2.25 | 2.70 | ||

| Thermal resistance | R | [m²K/W] | 0.0063 | 0.0074 | 0.0084 | 0.0089 | 0.0093 | ||

| Temperature Resistance | [ºC] | -40 to +80 | |||||||

Packing & Delivery:

Packing Details :1.Packing with plywooden case

2.Packing with plywood pallet

3.Packing according to client's requirements

Delivery Details : In commonly, 10-15 days after confirm order.

Related Products